Products & Technology

Composite Materials

Fiber Reinforced Plastics

We can provide “FRP” (fiber reinforced composite materials) made by many kinds of process methods.

Autoclave Molding

- The integrated facility of Aerospace parts under the condition of “ISO” and “Nadcap” is installed.

- Composite skin panel and Honeycomb sandwich panel could be produced.

- Adhesion of metal and Painting could be also produced.

Resin infusion Molding

- We can provide complex shape composite parts by original resin infusion system such as RTM, VaRTM and others.

RTMResin Transfer Molding

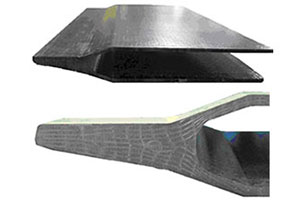

Unique composite component could be produced by implemented RTM process.

RTM injection equipment

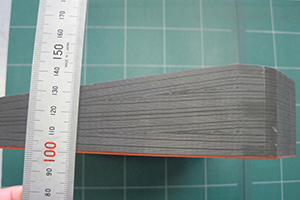

Thick and complex shape composite component

New ProcessAdvanced Resin infusion Molding

Composite materials can also be manufactured using low cost manufacturing process such as VaRTM.

Large scale parts and complex shaped parts could be provided by our developed resin infusion process.

Fuselage Demonstrator

Robot Arm

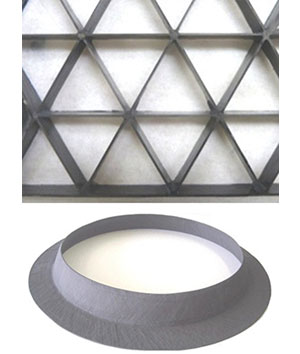

Grid & Tapared Ring

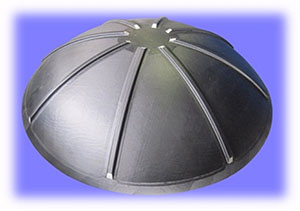

Pressure bulkhead demonstrator

Additional Techniques

We have special techniques for providing composite components by using the resin infusion process.

Resin Improvement

The new resin which is combined silica fine powder into epoxy resin which is developed for the improvement of fracture toughness of composites has developed.

This Nano-composite is named “Plamix”.

Fiber surface treatments

The special sizing for improved interlaminar strength between fiber and matrix has been developing.

We are also developing special treatments for improved the resin injection process.

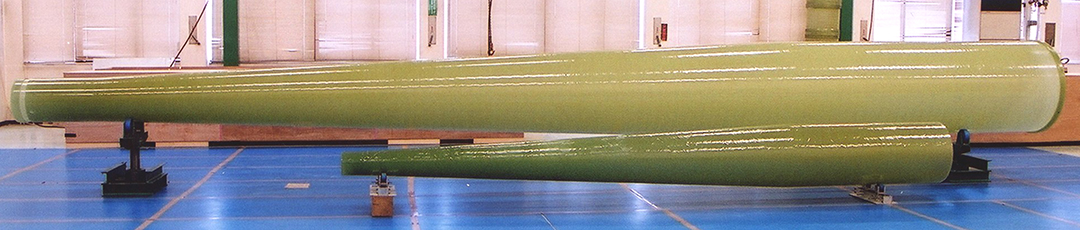

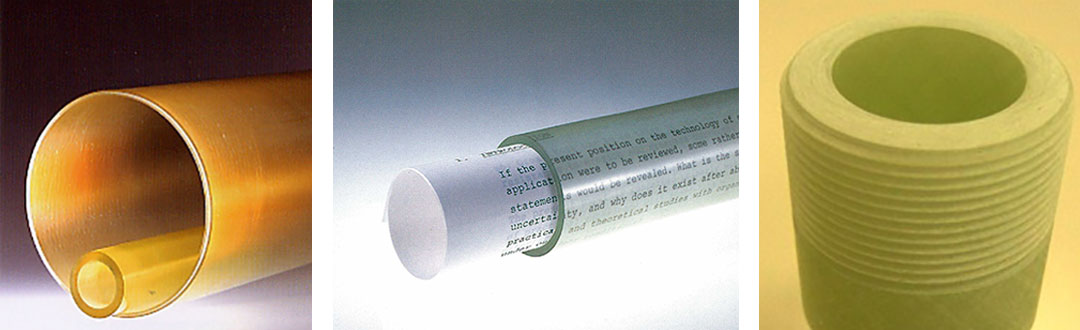

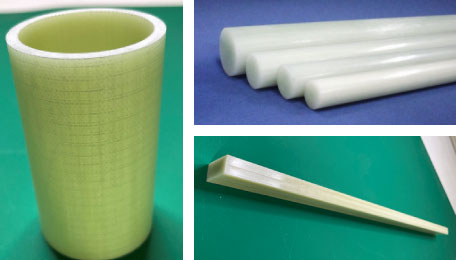

Filament Winding

- Large scale filament winding equipment at 10m length is installed.

- The composite parts at void less could be provided by our special technique.

- The pipe with taper can be also manufactured.

- Composite parts machined into various shapes and assembled are provided.

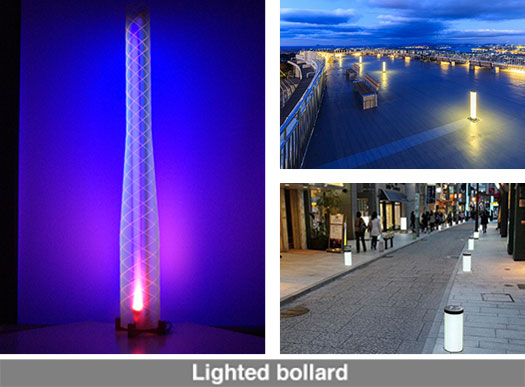

GFRP pipes are used for electrical insulators and saltwater desalination treatment materials.

Application to designer materials including structural using the transparency of GFRP of void free.

Pultrusion

- The Pultrusion equipment by using epoxy resin are installed.

- We can provide not only cylindrical shape but also complex cross section

shape such as L, T, U and others.

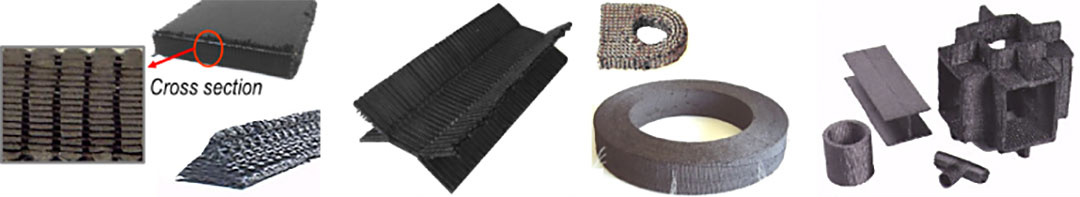

Other Composite Materials

- We are also developing other composite process such as FRTP, CMC, C/C.

FRTP : Fiber reinforced Thermoplastics

CMC : Ceramic Matrix Composite

C/C : Carbon-carbon Composite

Preform (Fiber Reinforcement)

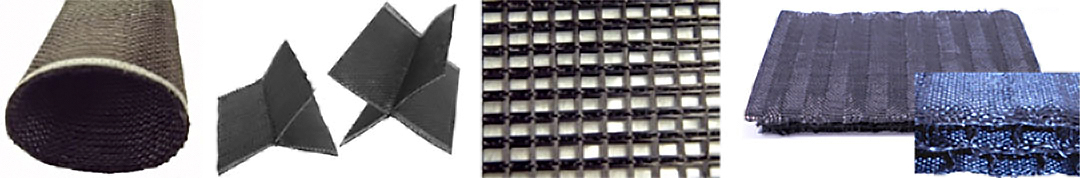

Textile Reinforcement

Shikibo has been developing special fiber reinforcements for composite materials based on our original textile technology.

3D Preform

- We have many kinds of 3D textile preform manufacturing process to satisfy requested property.

2D Woven Preform

- We can provide not only 2D flat fabric but also complex shaped fabrics.

UD Fiber Placement Preform

- Based on our original 3D textile technology, unique UD laminate textile preform could be also provided.

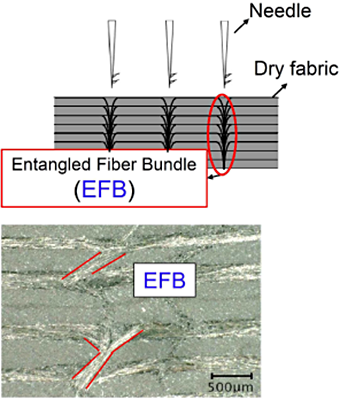

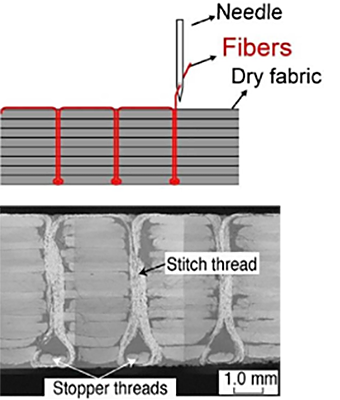

Z Direction Reinforcement

- As the additional technology for improvement of disadvantage point of composite, new reinforcement method for through the thickness direction has developed.

Z anchor

In-plane years are entangled with each other

F anchor

Inserting additional Z direction fiber

Stitching

Connecting of layers by stitching

Metal Parts (Marching for metal alloy)

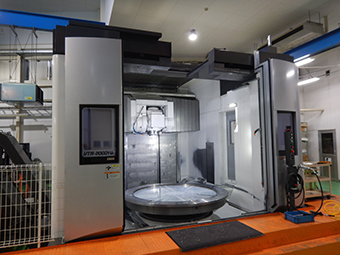

Vertical Machining Centers & Turning Center

The large scale engine parts have been providing by using special machining centers.

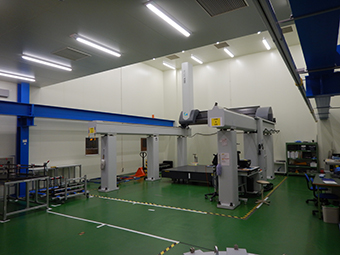

Coordinate Measuring Machine

Large scale Coordinate Measuring Machine was installed

Paint Booth

Not only composite but also metal components could be painted.

Inspection & Testing

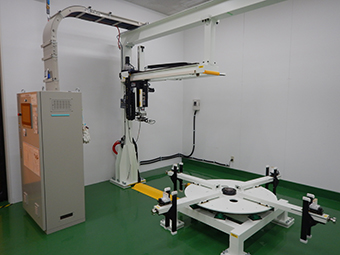

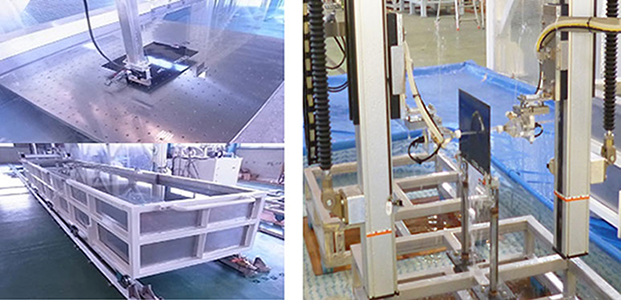

Non-destructive Inspection testing

Large scale ultrasonic inspection equipment have been installed along with Level III engineers.

Fluorescent penetrant Inspection

According to the scale of machining center, PT test equipment has installed.

Physical properties testing

We have also installed mechanical and thermal property testing equipment for the process control.

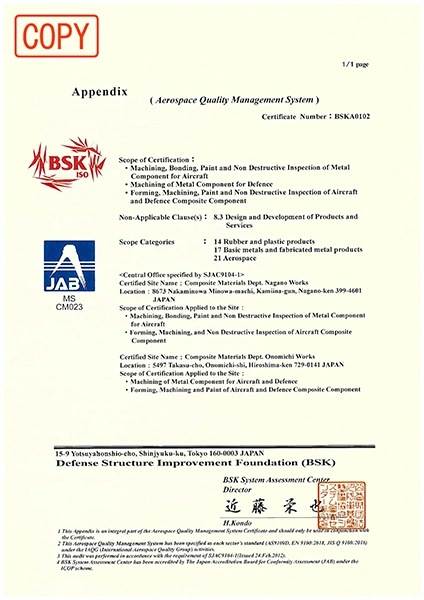

Quality Assurance

Shikibo has obtained certifications required for aircraft parts manufacturing under our quality assurance system.